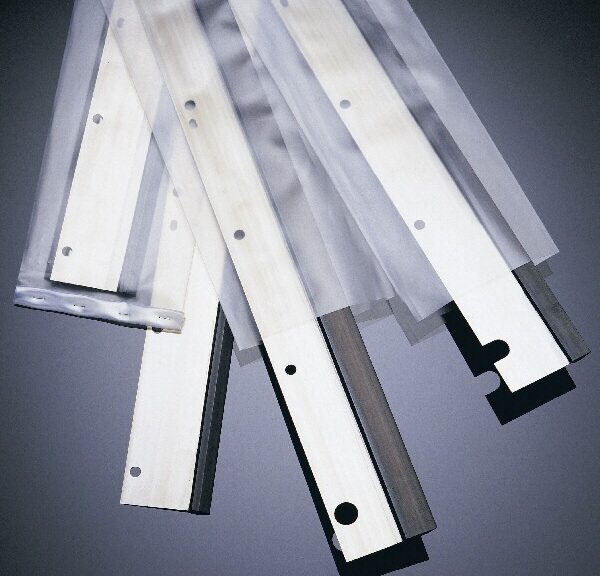

Wash Up Blades For Offset Lithography Components

The wiper blade is an essential part that oscillates the offset press before the next color feed. The knife grinding services are used to scrape off ink residue and facilitate the rollers and feeders inside the printing unit. Depending on the system and installation conditions, the bars have a completely unique design.

Wash up edge cut throat

Conventional Cutthroat Edge a traditional razor with components. It is a simple steel blade with holes, grooves or contours suitable for mounting in the holder and a rubber gasket on the front of the curler. Some legacy blade models must be obtained for some Heidelberg and mods.

Swab up Edge Pliable

Plastic sponge razorblade with new technology to improve routine Overgaard Company has developed a completely new generation of blades. This is because both long-term and short-term print jobs require heavy use of conventional inks and in addition require higher overall performance to stay competitive.

Wash up blade p is a thermoplastic fabric that can be machined to very small tolerances. That’s why we’ve given the blade a completely unique profile, developing a completely unique tactile neighborhood between the blade and the curler allowing for paint scraping and cleaner residue. This generation shortens cleaning time by about one third compared to conventional cleaning time of traditional cleaning blades. This reduces the use of cleaning services. Harm the atmosphere. Cleaning blade cleaning profile another advantage of the larger molecular resin that we use is the best resistance to abrasion and chemicals compared to all local conventional detergent suppliers.

Predictable

Scrubbing sharp edge often indentation inside the latex burrs and scrape towards the edges of the vibrating curler, reducing overall cleaning performance. With the current generation of Wash up blade plastic, this problem is gone and it is spreading gradually and evenly. Important because of the fabric capacity of the curler, but now there are larger capacity increases. So our Plastic blade domestic combines durability, clean ability and conservational friendliness.

- Cleaning edge connected to the holder

- Rinse the slide connected to the printing display place

- Launder the blade during spring-cleaning

- Many panty spring-cleaning explanations

Cruise our catalog to find the best cleaning razorblade for your maneuver. If the laundry slide you want is not listed, please communication us unswervingly.

By sliding the tip of the cleaning blade, the time to move back and forth is shortened. Remove and clean the screw his head and the ink his pan using the Omission Slope, a state-of-the-art blade system designed to simplify blade changes, reduce downtime, clean and stop Reject cumbersome systems.

Well-suited

With a wide range of printers, his omission Landfill allows teams to change blades in less than a miniscule without the need for equipment or recalibration. Save time and currency by merely swiping, gliding and updating your knife-edge. For more information visit our website: www.davisandjenkins.com.au